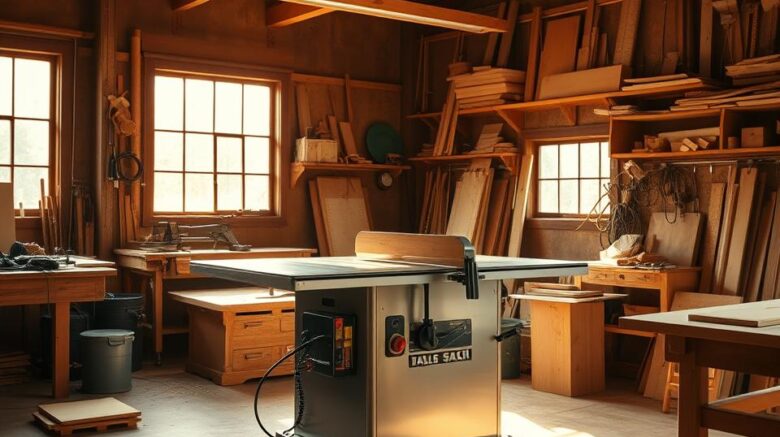

Samach: Home Furnishings Woodworking Equipment Experts

Ever pondered what it requires to convert uncooked materials into high-quality finished products? The solution is found in exactness, innovation, and the correct implements. Samach leads this market, delivering dependable answers for modern manufacturing requirements.

Armed with extensive experience, Samach has become a top moniker in the field. Their advanced edge banding machine aim to supply incomparable accuracy and effectiveness. Whether you are a specialist or a beginner, their systems secures every project satisfies the most rigorous benchmarks.

From innovative equipment to dependable assistance, Samach delivers all you require to thrive. Discover more about their innovative solutions by visiting www.samach.cn. This article will guide you through the essential aspects of their products, helping you make informed decisions for your endeavors.

Introduction to Samach and Furniture Woodworking Machinery

Exactness and ingenuity form the bedrock of current fabrication, and Samach masterfully offers both. Armed with years of expertise, Samach has become a trusted name in the woodworking industry, offering advanced solutions for professionals and hobbyists alike.

Samach’s expertise lies in combining classic workmanship with modern innovations. Their carpentry equipment are designed to meet the strictest criteria of accuracy and efficiency. From intimate tasks to industrial-scale production, Samach supplies the instruments necessary for success.

Samach’s Background and Expertise

Samach’s journey began with a focus on quality and innovation. Currently, they stand as an international frontrunner in the woodworking machinery industry. Their team of experts ensures every product is built to last, offering reliability and performance that professionals trust.

Ranging from CNC routers to edgebanders, Samach’s catalog accommodates varied requirements. Their equipment are designed to manage intricate operations effortlessly, rendering them an optimal pick for the woodworking industry.

Web Address and Reliable Offerings

For more information on Samach’s innovative solutions, visit www.samach.cn. Their online platform delivers in-depth details about their catalog, service offerings, and worldwide showrooms. Samach’s focus on superior standards renders them a dependable associate for specialists around the world.

| Characteristic | Detail |

|---|---|

| RPM Spectrum | 12,000 to 18,000 r/min |

| Work Speed Range | 1 to 15 m/min |

| Maximum Cutting Length | 3100 millimeters |

| Central Saw Motor Wattage | 5.5 kW |

| Warranty Period | 12 Months |

Samach’s machines are backed by industry-leading warranties and ISO 9001 certification. Their global presence spans countries like Vietnam, Brazil, and South Korea, guaranteeing availability to clients globally.

Exploring the Realm of Carpentry Equipment

From manual tools to advanced systems, carpentry devices offer diverse solutions for each task. Whether you are experienced or just starting out, comprehending the distinctions between manual and robotic machinery is key to success.

Overview of Manual and Automatic Machinery

Hand-operated devices, such as wood lathes, demand direct control and suit finer, intricate work. They offer precision but demand more time and effort. In contrast, robotic systems such as CNC machines simplify production with reduced human involvement. They are ideal for extensive assignments and elaborate patterns.

Key differences include:

- Manual systems save costs though operate at a slower pace.

- Automated equipment improves effectiveness and steadiness.

- Each variety serves distinct requirements within the carpentry sector.

Key Features and Benefits for Woodworkers

Top-notch equipment is characterized by its accuracy, user-friendliness, and capacity to process diverse substances. State-of-the-art systems secure steady performance, even on robust timber. As an illustration, CNC machines deliver unparalleled precision, and wide belt sanders yield silky textures.

Gains involve:

- Boosted efficiency and lowered waste.

- Upgraded safety measures for users.

- Adaptability to evolving project requirements.

The woodworking industry continues to embrace innovative materials and technology, making modern machinery more reliable and efficient than ever.

Guide for Choosing the Best Woodworking Devices for Furniture Crafting

Selecting the proper tools is the initial move to obtain impeccable outcomes in every task. Whether building cabinets or executing elaborate blueprints, the equipment chosen is critical. This overview will help you understand the categories of machinery provided and methods to assess their caliber for your requirements.

Grasping Diverse Machinery Varieties

Ranging from surface planers to joinery apparatus, a broad spectrum of equipment is tailored for distinct jobs. Each variant is intended for a particular function within production. As an example, planers are perfect for flattening surfaces, whereas joinery tools secure exact bonds between components.

Here’s a quick breakdown of common equipment types:

- Flattening Devices: Optimal for leveling and polishing surfaces.

- Assembly Devices: Secures exact and robust joints.

- Computerized Numerical Control Systems: Suited for elaborate blueprints and industrial output.

Measuring the Caliber of Machinery

Opting for superior devices is essential for steady performance. Identify traits including longevity, accuracy, and straightforward maintenance. Robust equipment boosts manufacturing efficiency and diminishes idle periods and servicing expenses.

Take into account the following benchmarks:

- Durability: Examine the construction and components.

- Accuracy: Confirm that the device produces exact performance reliably.

- Maintenance Friendliness: Choose machines that allow for straightforward servicing and maintenance.

Assessing these criteria helps you procure machines that satisfy your demands and offer lasting worth.

Essential Accessories and Technological Advances

In today’s dynamic production environment, add-ons and innovation are fundamental to improving output. From innovative belting solutions to advanced automated systems, these components are transforming how machines operate. This section examines the transformative technologies molding tomorrow’s production.

Innovative Belting Solutions and Edge Banding

Belting methods such as trailroll belts and sandbelts are transforming precision in machinery. These accessories ensure smooth operations, especially in tasks like edge banding. Specifically, edge banding tools offer meticulous outcomes, rendering them essential for premium manufacturing.

Dedicated feeding mechanisms and metallic parts boost robustness further. For example, rubber and metal rollers are essential for sanding and calibrating machines. Such components maintain uniform functionality, regardless of challenging settings.

Employing CNC, Lathes, plus Other Innovations

CNC machines and lathes are at the forefront of technological advancements. CNC systems automate complex tasks, reducing manual labor and increasing precision. Conversely, lathes are vital for crafting consistent parts, thereby improving both aesthetics and performance.

They merge flawlessly with additional elements, guaranteeing that each unit is handled perfectly. From planing machines to brushing systems, each part contributes to a streamlined production process. This culminates in remarkable gains in both excellence and productivity.

By embracing these innovations, production processes become more reliable and efficient. Whether it’s through advanced belting solutions or automated systems, technology continues to push the boundaries of what’s possible.

Industry Shifts and Technological Breakthroughs in Carpentry Equipment

The woodcraft machinery industry is evolving substantially due to innovation and market pressures. Boasting a worldwide value of USD 4.86 billion in 2023, projections indicate growth to USD 7.77 billion by 2032. The surge is powered by technological strides in machines and broader utilization of novel substances.

Impact of Global Market Shifts and COVID-19

The COVID-19 pandemic temporarily disrupted production and sales, causing delays in supply chains. However, the industry adapted quickly by integrating digital solutions and smart manufacturing technologies. As an instance, firms such as SCM Group upgraded their service provisions to satisfy changing customer demands.

Worldwide economic changes have similarly affected the appetite for woodworking machinery. Europe, which held a 40.53% market share in 2023, continues to lead due to its focus on sustainable practices. Conversely, the Asia-Pacific zone is predicted to register the fastest expansion, fueled by demographic increases and higher disposable incomes.

Innovations and Outlook for the Future

Technological advancements are shaping the future of the industry. CNC systems and automated machines are becoming standard, offering precision and efficiency. These advancements are notably useful for industrial-scale production and sophisticated projects.

Innovative materials such as Cross-Laminated Timbers (CLTs) are growing in appeal. These materials are not only sustainable but also enhance the durability and functionality of products. As a result, manufacturers are investing in machinery that can handle these advanced materials.

| Market Trend | Effect |

|---|---|

| Adoption of CNC Technology | Enhanced accuracy and productivity |

| Increase in Green Materials | Improved longevity of products |

| Expansion in the Asia-Pacific Area | Increased economic potential |

Anticipating the future, the sector stands ready for additional breakthroughs. Client desires for tailor-made and green practices will persist in fueling innovation. Leveraging these developments allows companies to keep pace and address the challenges of a dynamic marketplace.

Enhancing Manufacturing through Accuracy and Industrial Innovations

Productivity and precision power today’s manufacturing processes. In order to secure uniform results, the industry turns to cutting-edge machines and meticulous processes. This part investigates the integration of advanced approaches to refine processes and boost product excellence.

Precision Milling, Edgebanding, and Cabinet Making

Accurate milling is vital for crafting detailed motifs and achieving homogeneity in every piece. Advanced CNC systems automate this process, reducing errors and enhancing speed. Such machines are especially important in cabinet fabrication, where precision is paramount.

Edge banding, an additional vital procedure, guarantees smooth textures and longevity. Contemporary edge banding equipment incorporates custom feed mechanisms for steady performance. This method is critical for top-tier production, particularly for personalized assignments.

For cabinet making, precision equipment like CNC routers and joinery machines are game-changers. They tackle elaborate patterns smoothly, making sure every part integrates seamlessly. This level of accuracy minimizes waste and maximizes efficiency.

Approaches to Boost Manufacturing

Integrating precision parts and advanced feed systems can significantly improve production workflows. Such parts secure efficient performance and lessen operational lulls. For instance, robotic feed systems keep material delivery steady, thus boosting general effectiveness.

Alternatively, utilizing modern machines for recurring assignments that not only quickens production but also secures uniform outcomes in each piece. Automating operations allows companies to direct efforts toward maintaining quality and fostering innovation.

The Role of Precision in Quality Assurance

Accuracy forms the bedrock of quality assurance in industry. State-of-the-art machines guarantee that each cut, bore, and polish conforms to precise standards. This degree of exactness is essential to uphold lofty standards and consumer anticipations.

For example, computerized systems enable intricate coding, so that each piece is handled to perfection. This reduces errors and enhances the final product’s durability and functionality. Precision equipment also minimizes material waste, contributing to cost savings.

By embracing precision and advanced technology, manufacturers can optimize their production lines. This not only improves efficiency but also ensures every project meets the highest quality standards.

Last Considerations and Forward Moves for Woodworking Perfection

Reaching peak quality in manufacturing demands proper equipment, accuracy, and an innovative mindset. In this piece, we examined how cutting-edge machines and modern strategies can reshape your tasks. Be it CNC systems or niche equipment, the proper instruments secure both productivity and excellence.

To take the next step, consider integrating high-quality machines into your workflow. Navigate to www.samach.cn to discover personalized answers and specialist aid. Their focus on precision and consistent performance establishes them as a reputable collaborator in the market.

Welcome the freshest developments and match your project targets with state-of-the-art solutions. Concentrating on perpetual enhancement and utilizing the proper service enables exceptional outcomes. Let innovation drive your success and elevate your production to new heights.